About

April 13, 1942 - the works was founded by the decision of the State Committee of Defense

July, 1942 - the first product was manufactured

July 11, 1945 - the works was awarded the Order of Lenin

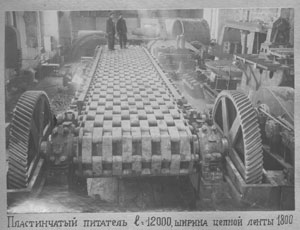

1945 - serial production of plate feeders has begun (more than 3000 feeders have been manufactured)

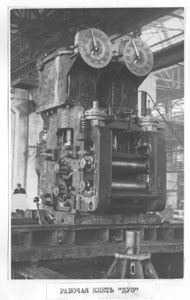

1948 - the first electric-weld tube plant was manufactured (over 70 plants have been manufactured)

1950 - production of blades for hydroturbines has begun. All turbines of home power stations are equipped with blades under EZTM brand (over 700 blades have been manufactured). Production of oil film bearings, section mills, forge manipulators and crushing equipment has begun.

1952 - the 40-160 tube-rolling plant for production of ball bearing tubes was put into operation (Pervouralsk);

- the unique oil film bearing was manufactured, the works' specialists were awarded with the State Prize of the USSR

1953 - the first 650 electric-weld tube plant for production of spiral welded tubes was put into operation (Mariupol)

1955 - the first 820 electric-weld tube mill for production of gas pipelines was put into operation (Chelyabinsk)

1956 - production of ball-rolling mills has begun

1958 – production of cold-rolling tube has begun

February 8, 1963 – according to the decision of the Council of Ministers the works specialized in production of tube, light section and special mills

1963 - the plant of continuous tube lap-welding was put into operation (Chelyabinsk). The designers were awarded with the Lenin Prize of the USSR

1966 – inventions were patented abroad for the first time (USA, Germany, Great Britain)

1967 - rated output of the 30-102 tube-rolling plant was achieved (Pervouralsk). The works' specialists were awarded with the State Prize of the USSR

1968 - gas pipelines of 1120 mm diameter were manufactured in the 1020-1220 electric-weld tube mill.

- the 100th cold tube-rolling mill was manufactured; development engineers were awarded with the State Prize of the USSR.

1971 - the 20 000th oil film bearing and 3000th hot-blast valve for blast furnaces were manufactured.

1972 - the works' specialists were awarded with the State Prize of the USSR for production of a range of cross-rolling mills

1974 - the largest tube electric welding plant for production of tubes of 1620 mm diameter was put into operation (Khartsizsk)

1976 - the 3/8 "-1" continuous butt-welding plant was put into operation (Taganrog); its designers were awarded with the State Prize of the USSR

1978 - the first rolled axis for railway transport was manufactured in the equipment designed by the EZTM together with VNIIMETMASH (Dneprodzerzhinsk). The designers were awarded with the State Prize of the USSR

1979 - production of seamless tubes in semi-continuous plants has begun. The plants were put into operation in Kamensk-Uralski and in Dnepropetrovsk. The equipment designers were awarded with the State Prize of the USSR.

- serial production of toothed couplings has begun.

1982 - specialists of EZTM and VNIIMETMASH were awarded with the State Prize of the USSR for design and manufacture of automatic ball-rolling mills

1983 - complex of machines for production of economic oil-gas pipelines with diameter up to 530 mm was designed and put into operation. Its designers were awarded with the State Prize of the USSR.

- tube electric welding mill for production of aluminum tubes was designed. Its designers were awarded with the Prize of the Council of Ministers of the USSR.

1986 - the ТПА-80 tube-rolling plant was put into operation in Sinarsky Pipe Works. Hot rolling of small diameter tubes was performed in it for the first time.

1988 - the plant for production of vessels was put into operation (Mariupol Illich Iron & Steel Works).

- the 700 medium section mill was designed and delivered to Nigeria;

- the 160 universal cold-rolling tube mill was designed and delivered to Chelyabinsk;

since 1991 – it has been designed and delivered:

the 400 medium section beam-rolling mill (Norway);

the 1020 electric-weld tube plant (Vyksa Steel Works);

the special sizing mill (Czechia);

the 25-114 electric-weld tube plant (Bulgaria);

series of cold-rolling tube mills (India);

the 15-50M electric-weld tube plant (Brasilia)

4 unique cold-rolling mills for production of stainless large diameter tubes (China)

In February 1998 - bearing ring rolling plant was successfully put into operation at "Timken" (USA).

- the 40-80 ball-rolling mill was put into operation (Uzbekistan)

- the 20-60 ball-rolling mill was put into operation (Germany and India)

1999 - three exit sides of piercing mills for "Timken" (USA) were reconstructed.

2002 - power wire production line for Klyuchevski Ferro-Alloys Plant, Sverdlovsk region, was manufactured and put into operation.

2003 - standard range of quickchangeable constricting devices (QCD 100, 150, 200, 300, 400, 700) for enterprises of gas industry was developed and manufactured. The Konstantinovsky Palace - Palace of Congress (St. Petersburg) was one of the sites where QCD 200, 300 was delivered to.

2004 – the quality management system in the field of "design and manufacture of oil film bearings for rolling mills and gear couplings" was certificated by Britain Standard Institute (BSI). Certificate № FM 90597 was given.

- a contractor design of reconstruction of the 1020 tube electric welding plant had been completed and the first set of equipment was manufactured (Vyksa Steel Works). The aim of the reconstruction was to produce tubes 1420 mm diameter.

- the 60-160 cold rolling mill for NFC (India) was designed and manufactured. The problem of production of round and square tubes from billets with the diameter more than 120 mm was solved for the first time.

2005 - the quality management system in the field of "Design, manufacture and maintenance of rolling, blast furnace and mining equipment and their spare parts including oil film bearings for rolling mills and gear couplings" was certificated by Britain Standard Institute (BSI).

- the first set of the equipment for Vyksa Steel Works was put into operation. The second set of the equipment of the 1020 tube electric welding plant was designed and manufactured. An assembly-welding mill, a mill for outer and inner welding and tube testing and repairing equipment were designed and manufactured by EZTM JSC in the frames of the delivery contract of the third set of the equipment.

- the 40-8 cold rolling mill with drive vertical arrangement was designed and manufactured (Ukraine). It allowed to increase speed of the mill.

- the unique equipment of a piercing mill for was designed and manufactured (Seversky Tube Works).

- manufacture of a reduction mill has begun (Sinarsky Pipe Works). This mill allowed to reduce diameter of a billet made by steel continuous casting plant from 156 mm to 120-130 mm.

- modernization of the 2-40Б cold rolling mill has begun.

- representations of EZTM JSC in Singapore and Ukraine were opened.

2006

- Representative offices of "EZTM" JSC in UK and India were opened.

- Agreement on manufacture and delivery of equipment for modernization of reducing mill and cooling bed for TПA-80 line was executed with "Dnepropetrovsk Tube Works" JSC.

- Agreement on manufacture and delivery of rotary cement kiln was executed with PRUP "Krichevtsementnoshifer", Belarus.

- Agreement on manufacture and delivery of equipment for modernization of ТПА-50-200 mill, two 3-roll stands of reeling mill and equipment of sizing mill was executed with "Volzhsky Tube Works" JSC.

- Agreement on manufacture and delivery of sizing mill equipment was executed with "Sinara Tube Works" JSC.

- Agreement on manufacture and delivery of sizing mill equipment was executed with "Taganrog Metallurgical Plant" JSC.

- Agreement on modernization of ТПА-140 for "Izhora Tube Company" was executed with "Industrial Investment Company" Ltd.

- Agreement on manufacture and delivery of a reloader was executed with "Seversky Tube Works" JSC.

- "Tandem 1000" mill equipment for "Kirov Non-Ferrous Metal Processing Plant" JSC was designed and manufactured jointly with VNIIMETMASH.

- ХПТ 40-5 mill was launched into production.

- New КГД 1100 hot blast valve was designed.

- The quality management system of "EZTM" JSC was certified by external auditors of Britain Standard Institute (BSI) confirming compliance with BS EN ISO 9001:2000 (Periodical appraisal No. 2).

- "EZTM" JSC, Graebener Maschinentechnik GmbH & Co KG (Deutschland) and Fontijne Grotnes BV (The Netherlands) signed a protocol on cooperation in the field of design and supply of tube welding works equipment set for production of longitudinal welded tubes of large diameter. "EZTM" JSC was a general contractor and supplier of tube welding works equipment set in Russia and abroad under the protocol.

2007

- "EZTM" JSC celebrated its 65 anniversary.

- "EZTM" JSC was entitled as "Russian Company of high social efficiency".

- "400" piercing mill designed and manufactures by "EZTM" JSC in 2006 was put into service at "Seversky Tube Works" JSC.

- 3-roll stand of reeling mill was manufactured and supplied to "Volzhsky Tube Works" JSC.

- Sizing mill equipment was manufactured and supplied to "Volzhsky Tube Works" JSC.

- Sizing mill equipment was manufactured for "Sinara Tube Works" JSC.

- Sizing mill equipment was manufactured for "Taganrog Metallurgical Works" JSC.

- Equipment for ТПА 50-200 mill reconstruction was manufactured and supplied to "Volzhsky Tube Works" JSC.

- Equipment for reconstruction of ТПА-80 mill and cooling bad was manufactured for "Dnepropetrovsk Tube Works" JSC.

- Agreement on production of ТПА-200 breakdown mill equipment was executed with TMC-ArtRom"(Rumania).

- Rotary cement kiln equipment was manufactured for PRUP "Krichevtsementnoshifer" (Belarus).

2008

- The quality management system of "EZTM" JSC was certified by external auditors of Britain Standard Institute (BSI) confirming compliance to BS EN ISO 9001:2000.

- "EZTM" JSC was certified as a hot and cold rolls supplier of "TMC" JSC by "RosNITI" JSC auditors.

- The first stage of preparation for company environment security system development corresponding to ISO 14001 took place.

- ТПА 200 breakdown mill was manufactured and supplied to "TNC-ArtRom", Romania.

- Agreement on manufacture and supply of ХПТ 350-8 cold rolling mill was executed with TISCO, China.

- Equipment of assembling-welding mill No.1 and No.4 was manufactured and installed at "Chelyabinsk Tube Rolling Plant".

- Piercing mill for production of casing and oil-well tubing was manufactured and supplied to "Vyksa Metallurgical Plant" JSC.

- Agreement on manufacture and supply of a floor-charging machine was executed with VMZ "Krasny Oktyabr" ZAO.

- Agreement on supply of draw bridge equipment was executed with "Rostovavtomost" JSC.

- New hot blast valve 1100 of cowper stove was designed and manufactured for "Seversal" JSC.

- New hydrostatodynamic oil film bearings were mounted and put into operation in SMS Demag reversing cold rolling mill operating at "MMK" JSC.

- Spare parts for general overhaul of tube rolling shop No. 4 at "Interpipe NTZ" JSC were supplied.

- Apron feeders were manufactured and supplied to mining and processing enterprise "Erdenet", Mongolia.

- Jaw crusher ЩДС 12х15-F with complex jaw movement was designed and manufactured for "Orsk Kareroupravlenie" JSC.

- Titanium sponge crusher for titanium sponge processing line was designed.

2009

- Contract on manufacture and supply of four crushers for processing of titanium sponge was singed with "Yunnan Metallurgical Group" (China).

- Shopfloor assembly of eight crushers for processing of titanium sponge under terms of a contract concluded between "EZTM" JSC and "Pangang Group Titanium Industry Corp. Ltd", China, was completed.

- Equipment of a sizing mill manufactured by "EZTM" JSC and supplied to "Taganrog Metallurgical Plant" JSC successfully passed performance tests and reached its guaranteed performance.

- Mechanical equipment intended for opening of spans of the bridge over Don River in Rostov region was manufactured and supplied under an agreement between "EZTM" JSC and "Rostovavtomost" JSC.

- Steel grades increasing wear resistance of rolls were used in production.

- An orbital step-up gear for a generator of wind-driven power plant ВЭУ-1,5 with capacity of 1500 kW was designed.

- A representative office of "EZTM" JSC was opened in China.

- Quality management system of "EZTM" JSC was certified to be in conformance with ISO 9001:2008 by BSI.

- Equipment of a cold rolling mill ХПТ – 350 was manufactured and supplied to «TISCO» (China).

- Mechanical equipment and automation systems for modernization of a cold rolling mill ХПТ-55 were supplied to “Mashinostroitelny Zavod” (OAO MSZ), Electorstal city, Russia

- The following projects were implemented as a part of a modernization program of the procurement division:

- a steam-power press installed in a press-forging shop was replaced by a forging complex based on a 3000 press and a manipulator with capacity of 35 ton

- two heat treatment furnaces "Bosio", Slovenia, were put into operation in Machine Assembly Department No. 2

- a reheating furnace "Bosio", Slovenia, was put into operation in the press-forging shop

- a gas furnace "Bosio", Slovenia, for cementation of tooth gears with diameter of ≤1200 mm and weight of ≤ 1700 kg was put into operation

2010

- The CRTM 350-8 installed at "TISCO" (China) is put into operation. The 100% performance indices are reached.

- The loading tests of the CRTM 40-5 equipment installed at "SinTZ" JSC are successfully carried out.

- The modernization of CRTM 55 installed at "MSZ" JSC is carried out.

- The new thermolined model of hot-blast valve 900 mm OD is worked up.

- The new hot-blast valve 1300 with a hinge drive "AUMA" is shipped.

- The shipped mill rolls from the steel grade 150CrNiMo (С 1,4-1,6; Mn 0,5-0,8; Si 0,25-0,5; S≤0,05; P≤0,05; Cr 0,9-1,25; Mo 0,1-0,3) mastered in our production are put into operation by our Customers that confirms the high quality of the manufactured production.

- 8 crushers for processing of titanium sponge are shipped to the company "Pangang Group Titanium Industry Corp. Ltd", China.

- 4 crushers for processing of titanium sponge are manufactured and shipped for the company «Yunnan Metallurgical Group», China.

- Roller crushers for titanium and zirconium production are designed.

- The laboratory cone crusher intended for operation at titanium-magnesium plants is worked up.

- Putting of a new gear-milling machine in operation allowed to go over to regular production of ring gears up to 8 m OD with module up to 50 mm. Thus, there are ring gears for ball mills manufactured and shipped to the Customers:

- ring gear 5,050m OD for "Korshunovsky GOK" JSC,

- ring gear 4,482m OD for "GMK Norilsky nickel" JSC,

- 4 ring gears 4,416m OD for "Irkutskenergo" JSC,

- ring gear 7,830m for cement kiln as well.

- The unique tyre with weight more than 100 tn is shipped.

- There are optional feeders manufactured and shipped to the Customers:

- special feeder 2-24-99 for Sokolovo-Sorbayskoe GPO,

- special feeder 2-24-120 for "KrasnoselskStroyMaterialy" JSC,

- special feeder 1-24-120 for Granit RUPP.

- The Engineering Department specialists worked up the gearboxes of a new generation ЦКЦ2-630 and ЦКЦ2-560 for mining equipment drives instead of ЦКЦ2-1000 and ЦКЦ2-800. The gearboxes are manufactured and shipped to the Customers.

2011

- EZTM JSC developed, produced and introduced new equipment for modernisation of the tube electric-welding plant CEWP 20-76 of the Korolevsky Tube Works including:

- strip receiver;

- uncoiler;

- vertical stand;

- welding stand.

- EZTM JSC fulfilled the modernisation project for cold-rolling tube mills of the Sinarsky Pipe Works including:

- CRTM 55M of the right type;

- CRTM 55M of the left type;

- CRTM 90M

- Equipment for a tube electric-welding plant CEWP 20-60 of the Korolevsky Pipe Works was designed and manufactured.

- Equipment for transportation line of the tube electric-welding shop 3 of the Vyksa Steel Works was manufactured and installed.

- In accordance with the programme on improvement of technical standarts and reduction of production costs the following valves were designed and manufactured:

- hot-blast valve Ø1100 mm with a formed disk;

- hot-blast valve Ø1100 mm with a solid-forged disk;

- smoke valve Ø1100 mm.

- Equipment for ring furnace bottom Ø 20m for the Pervouralsk New Pipe Works, JSC was designed and manufactured.

- The contract was signed and equipment for jaw crushers ЩДП 5,9х8 and ЩДП 3,0х9 was designed.

- Mixing drum for the company "IMET-TEK", Slovenia was designed and manufactured.

- The following equipment was designed and manufactured under the re-equipment programme:

- balk tank of the mobile mixer;

- silos for regenerate and virgin sand;

- storage tank of regenerate;

- housing kit for recuperator of the furnace № 46;

- choke valve Ø700 mm for the exhaust duct system of the furnace № 46;

- housing kit for recuperator of the furnace № 48;

- choke valve Ø950 mm for the exhaust duct system of the furnace № 48.

2012

- The unique Cold Rolling Tube Mill 380 of pilger type was designed for production of seamless cold-rolled tubes made of carbon, alloyed and stainless steel grades.

- Two CRTM 55 and one CRTM 90 were successfully tested at Sinarsky Pipe Plant after their modernization.

- Ball rolling mill ШПС 30-100 was manufactured.

- A contract with "Teghout", JSC (Armenia) for the manufacturing of seven large feeders for the Teghout copper-molybdenum deposit was signed.

- EZTM consolidated its image of a reliable supplier of titanium sponge crushers: a contract with VSMPO AVISMA was successfully fulfilled at the domestic market. As for the foreign market, EZTM signed a contact and started production of four titanium sponge crushers for Tangshan Tianhe Titanium Industry Co. CHINA.

- Crushers ЩДП 5,9x8 and ЩДП 3x9 for Satka Iron Smelting Plant were produced.

2013

- The additional equipping of the piercing mill at shop T1 of Seversky Pipe Plant, JSC was provided.

- Special apron feeders 1-24-150A and 1-24-120A for "Nornickel", JSC were supplied.

- Special apron feeder 1-18-90B for"Gaisky Mining and Processing Enterprise" JSC was produced. Its design was made with account to the maximum reduction of the overall dimensions of its main components for the possibility of installation in the mines.

- Special feeder 1-24-150A with a reinforced belt and a sprocket shaft to it, an individual drive on the mechanism of slush removal and a special frame for installation of receiving hopper of the crusher were produced for Kovdorskiy Mining and Processing Enterprise, JSC.

- The technical project of AS-2110 gear box with cemented and ground gears for the cement mill ø2,6x13 drive was developed.

2014

- Transportation equipment was supplied to Vyksa Steel Works, JSC for TESA 203-530 thermal area for reconstruction.

- The equipment of the experimental longitudinal rolling mill was manufactured and assembled.

- The design of the cold rolling tube mill CRTM 65-6 was performed for the Indian customer.

- Pinion stand with half coupling was manufactured and shipped to "Isfahan Steel Company", Iran.

- Hot blast valve Dn2000 of new design with the possibility of existing spares (disk and rings) use was produced for "ArselorMittal Kryvyi Rih" JSC .

- Feeder 2-15-120 belts with corrugated working surface for increasing their service life were manufactured for Kovdorsky Mining and Processing Enterprise, JSC

- Special feeder 1-24-120B was produced for “Syr’yevaya Kompanya”, CJSC.

- Special gearbox ЦКЦ 2-630-370 for the feeder 1-24-90B with higher capacity was designed and manufactured.

- Special gearbox W3-480 for the drying drum was manufactured for Balkum LLC.

- -Crushers ЩДП - 15x21 were manufactured for Erdenet Enterprise Ltd. in Mongolia and ЩДП 9-12 was manufactured for Kryvyi Rih Iron Ore Plant, JSC in Ukraine.

2015

- Modernization of the drive of the piercing mill entry and exit sides was provided at Seversky Pipe Plant, PJSC.

- Universal screw rolling mill equipment was manufactured and delivered “Izhevsky opytno-mekhanichesky zavod” JSC

- Equipment for reconstruction of the railway bridge over the Svir River by Electrotechimport, LLC was manufactured and supplied.

2016

- The equipment of CRTM 280 for SFAE, Iran, was manufactured and shipped. I

- A contract for the supply of a piercing mill TRP 250 for Bakusteel Co., Azerbaijan was signed.

- Tube straightening machine was manufactured and supplied to Seversky Pipe Plant, JSC.

- Equipment for thermal area of the electric-weld tube shop of Vyksa Steel Works, JSC was manufactured and supplied.

2018

- Tube straightening machine was manufactured and supplied to Seversky Pipe Plant, JSC.

- Equipment for thermal area of the electric-weld tube shop of Vyksa Steel Works, JSC was manufactured and supplied.

2019

-

The Breakdown Mill equipment Screw Rolling Mill 50 was manufactured and put into operation at “Izhevsky opytno-mekhanichesky zavod” JSC (IOMZ);

-

The equipment for revamping of Screw Rolling Mill 500 was manufactured and shipped to SC "Chepetsky Mechanical Plant", Glazov City;

-

Cold Rolling Tube Mill 280 was erected in Iran;

2020

-

Tube straightening machine for tubes Ø168-370 mm and 8-stand Sizing Mill were put into operation at “Seversky Pipe Plant”, JSC of TMK Group;

2021

-

The equipment for Heating Furnace and Section Rolling Mill 250 was manufactured and shipped to the Republic of Cuba;

-

The equipment of the Cold Rolling Tube Mill 65 was manufactured and shipped to NFC, India. At the moment erection supervision is under process;

-

The contract with “Metalloinvest”, JSC for engineering and manufacturing of the equipment complex for ball manufacturing was signed. The complex will consist of two processing lines of Ball Rolling Mills 40-60 mm. Detail engineering has already been represented and equipment manufacturing and units completing has been started;

2022

-

The equipment of the two Cold Rolling Tube Mills 32 was manufactured and shipped to India;

-

The contracts for another five Cold Rolling Tube Mills for NFC, India, were signed and manufacturing orders have be issued;

-

More than 20 000 tons of equipment and spares were manufactured for metallurgical, mining and cement industries of the Russian Federation CIS members and other countries.