Gear clutch tooth shape is patented and meets all international standards. Tooth surface is heat-treated.

It is possible to design and manufacture special gear clutches with torque up to 1000.000 H m (up to 100 Tn m) on demand.

Gear clutch production is certified to BS EN ISO 9001:200 (certificate № FM 90597).

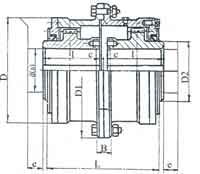

Gear clutch, type 1 № 9-19

|

Clutch number |

d, mm from…up to |

D, mm |

D1, mm |

D2, mm |

L, mm |

l, mm |

C, mm |

C1, mm |

B, mm |

e, min |

Max RPM |

Nominal torque, кНм, up to |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

МЗ-9 |

100…160 |

335 |

430 |

210 |

332 |

165 |

5 |

30 |

50 |

40 |

1050 |

3 |

|

МЗ-10 |

120…180 |

395 |

490 |

260 |

360 |

180 |

5 |

35 |

50 |

40 |

850 |

5 |

|

МЗ-11 |

140…210 |

450 |

545 |

300 |

392 |

200 |

5 |

35 |

60 |

40 |

750 |

7,1 |

|

МЗ-12 |

160…240 |

495 |

590 |

340 |

472 |

240 |

5 |

40 |

60 |

40 |

665 |

10 |

|

МЗ-13 |

180…270 |

555 |

680 |

380 |

516 |

260 |

7,5 |

45 |

70 |

50 |

600 |

15 |

|

МЗ-14 |

200…300 |

610 |

730 |

420 |

562 |

280 |

7,5 |

50 |

70 |

50 |

530 |

20 |

|

МЗ-15 |

220…340 |

660 |

780 |

450 |

640 |

320 |

7,5 |

50 |

70 |

50 |

500 |

25 |

|

МЗ-16 |

240…380 |

755 |

900 |

530 |

700 |

350 |

10 |

- |

90 |

50 |

430 |

37,5 |

|

МЗ-17 |

270…450 |

855 |

1000 |

600 |

800 |

400 |

10 |

- |

90 |

50 |

375 |

56 |

|

МЗ-18 |

340…500 |

950 |

1100 |

670 |

910 |

450 |

15 |

- |

110 |

60 |

330 |

75 |

|

МЗ-19 |

380…550 |

1050 |

1250 |

750 |

1090 |

485 |

15 |

- |

110 |

60 |

300 |

100 |

Clutch reference code example: clutch М39 with bush 100 and 120 mounting bore diameter - М 39-100-120.

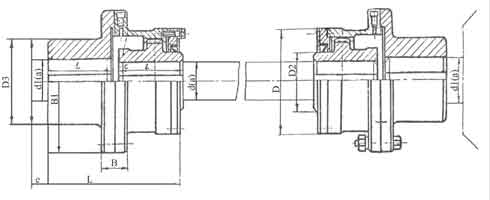

Gear clutch, type 2 № 9-19

|

Clutch number |

d, mm from…up to |

d1, mm from…up to |

D, mm |

D1, mm |

D2, mm |

D3, mm |

L, mm |

l, mm |

C, mm |

B, mm |

e, mm |

Max RPM |

Nominal torque, кНм, up to |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

МЗ-9 |

100…160 |

100…190 |

335 |

430 |

210 |

280 |

331 |

165 |

10 |

50 |

40 |

1050 |

3 |

|

|

МЗ-10 |

120…180 |

120…210 |

395 |

490 |

260 |

320 |

366 |

180 |

10 |

50 |

40 |

850 |

5 |

|

|

МЗ-11 |

140…210 |

140…240 |

450 |

545 |

300 |

380 |

405 |

200 |

10 |

60 |

40 |

750 |

7,1 |

|

|

МЗ-12 |

160…240 |

160…280 |

495 |

590 |

340 |

420 |

485 |

240 |

10 |

60 |

40 |

665 |

10 |

|

|

МЗ-13 |

180…270 |

180…300 |

555 |

680 |

380 |

480 |

524 |

260 |

15 |

70 |

50 |

600 |

15 |

|

|

МЗ-14 |

200…300 |

200…340 |

610 |

730 |

420 |

520 |

561 |

280 |

15 |

70 |

60 |

530 |

20 |

|

|

МЗ-15 |

220…340 |

220…360 |

660 |

780 |

450 |

560 |

644 |

320 |

15 |

70 |

50 |

500 |

25 |

|

|

МЗ-16 |

240…380 |

240…430 |

755 |

900 |

530 |

650 |

708 |

350 |

20 |

90 |

50 |

430 |

37,5 |

|

|

МЗ-17 |

270…450 |

270…500 |

855 |

1000 |

600 |

750 |

805 |

400 |

20 |

90 |

50 |

375 |

56 |

|

|

МЗ-18 |

340…500 |

340…550 |

950 |

1100 |

670 |

820 |

910 |

450 |

30 |

110 |

60 |

330 |

75 |

|

|

МЗ-19 |

380…500 |

380…620 |

1050 |

1250 |

750 |

920 |

975 |

485 |

30 |

110 |

60 |

300 |

100 |

|

Clutch reference code example: clutch with intermediate shaft and bores in bush 100 and half clutches 140 and 180 – Clutch М3П9-100-140-180.

It is possible to produce gear clutches according to GOST 5006-83 and TU 24.012309-84.