The mill is a compact, high-effective, low energy complex with a unique capability to produce bar section and seamless tubes at one and the same equipment.

Purpose and application area

The mill is designed on the basis of a long-term rolling experience and original engineering developments. It is intended for round bar section and tubes economic production in operational volumes from any wrought metals and alloys by means of screw rolling with comparatively low investment spending.

New rolling equipment effective application area includes :

• Versatile production of small and super small batches of precision bars and tubes in the extended range of grades and sizes which results in complete meeting regional demands.

• Creation of mobile rolling units within engineering enterprises in order to form metal usage economic structure, involve bar wastes, off-gauge ends and other waste in the production process.

• New materials and technologies R&D as the most effective and available means intended for different metal billets hot plastic deformation.

Design and its peculiarities

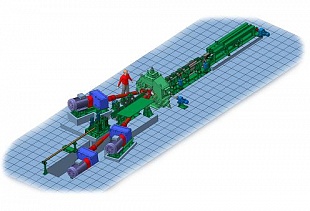

The mill equipment includes a front table with a pusher, a working stand, a receiving, centering and product ejecting table, the main drive.

The front table and main drive design is performed using technical decisions experienced through a long-term practice. The table is designed in the form of a height – adjusted chute and is provided with a bumpless billet reception and stowing.

The pusher is of the friction type with an electro-mechanical drive. The main drive is an individual gear one with ball spindle devices.

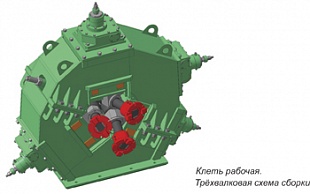

The working stand consists of a housing in the rectangular bores of which cassettes with working rolls and the mechanisms for their moving are installed at the angle of 120° to each other.

The differential peculiarity of the present stand is the production break scheme of its housing which is performed at the angle of 60° to the foundation and passes through the axis of one of the cassettes. The stand is also characterized by a presence of an upper line setter placed in the stand cover bore in parallel to the mechanism foundation.

This housing design gives a possibility to change stand configuration from three high rolling scheme to a two high one by means of light manipulations after cover removal. At this point, change of the cassettes with breakdown rolls to the cassettes with piercing rolls and lines installation is performed at a special stand.

Receiving, centering and product ejecting table has a side ejecting scheme and is performed as sequentially placed and linked three roller type centering devices with a hinged upper roller. The piercing process is performed with assist of centering sleeves, the arrangement of which is carried out by a special mechanism.